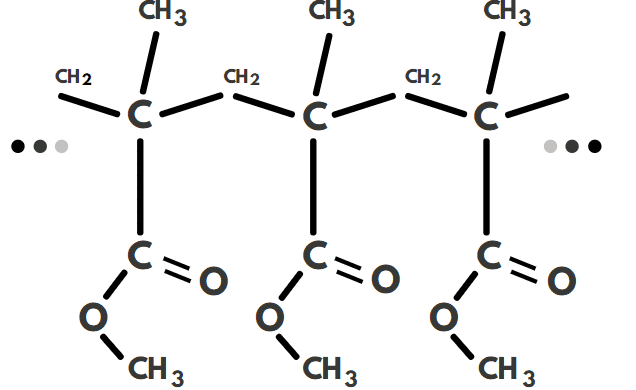

PMMA, commonly known as Plexiglass, has many advantages.

This material offers transparency akin to glass, as well as incomparable top-of-the-range finishes.

And when it comes to reliability, our PMMA cases are long-lasting and can be reused.

When it comes to personalisation, we offer digital or hot stamping of

your logo or message on your cases – just ask our team!

PMMA can be used for a wide range of applications, but is particularly well suited to the luxury goods, POS and cosmetics markets.

The design of PMMA parts and the transformation of this material by injection are among our company’s historic specialities. Our expertise in the optical sector has been put to good use in luxury packaging.